CANADA’S LEADING COST AND QUALITY PERFORMANCE PURGING SOLUTION FOR INJECTION MOLDING AND BLOW MOLDING

INJECTION MOLDING

The Standard purging process does not require PurgeMax® mixing with purging resin. Soaking prior to purging is not required either.

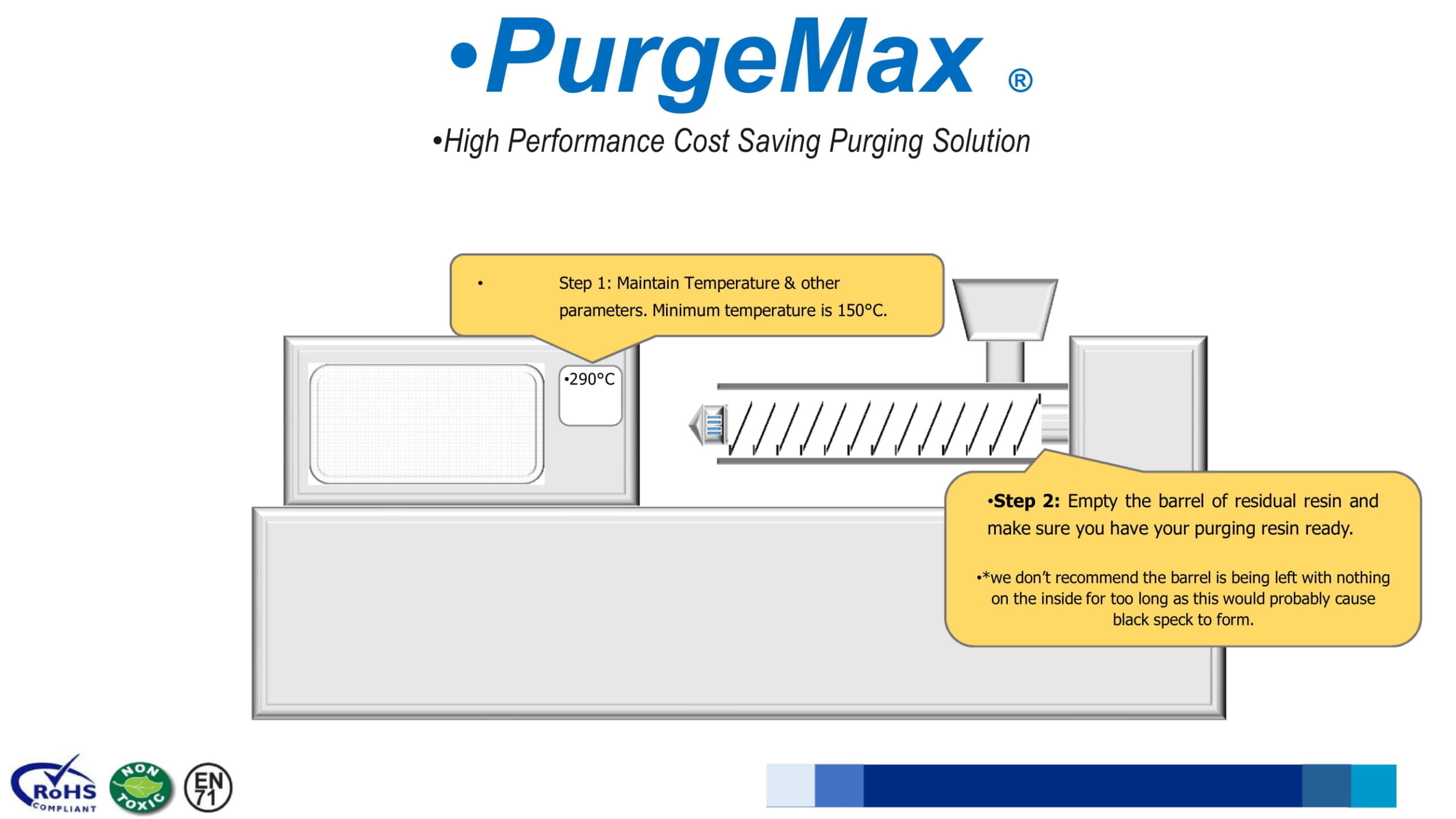

Step 1

Maintain processing profile for resin in the machine. (Minimum temperature 135°C)

Step 2

Empty the screw and barrel of residual resin.

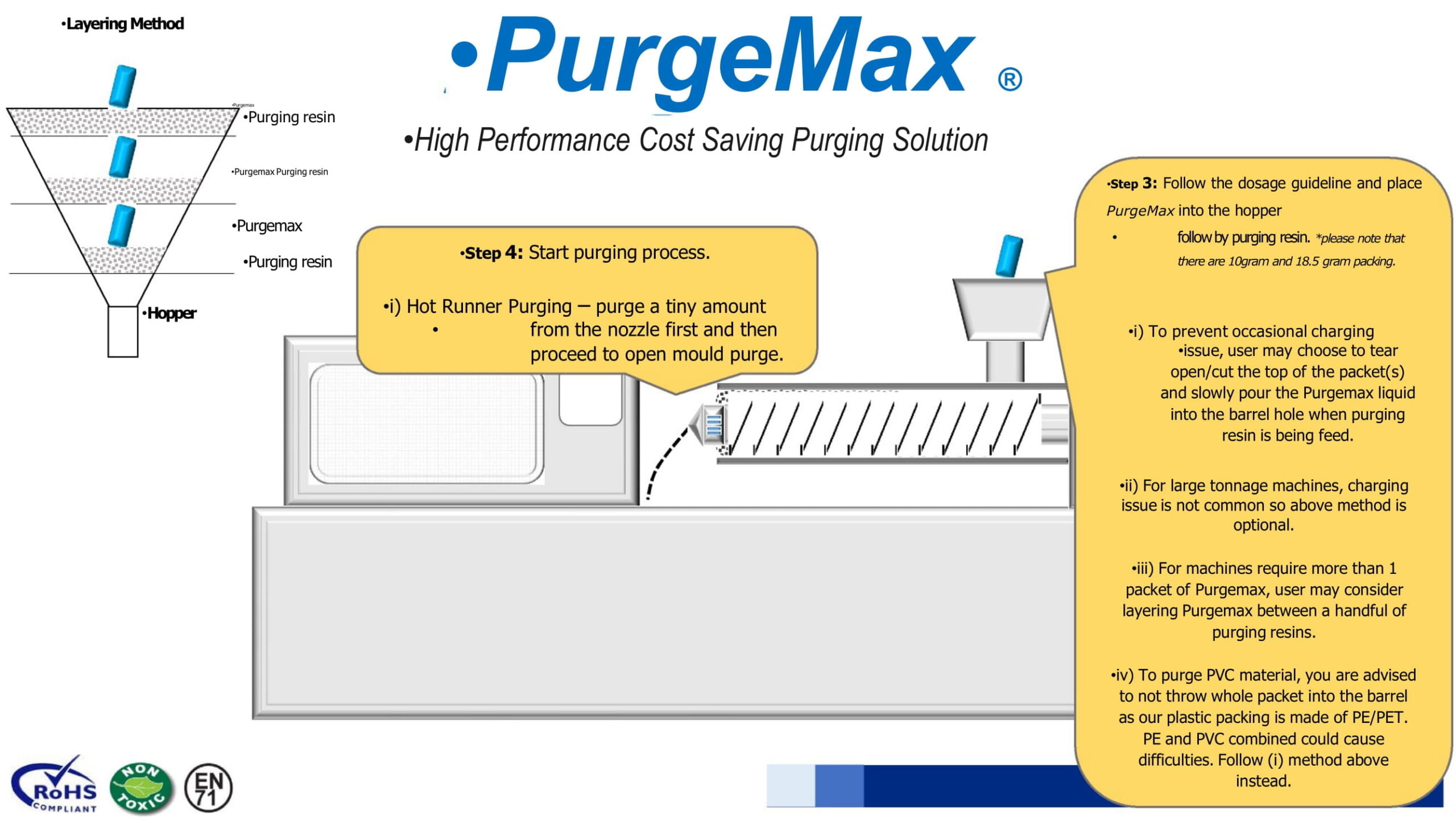

Step 3

Place PurgeMax directly into hopper and follow immediately with purging resin. *

Step 4

The Purging process can be done by purging or injection. **

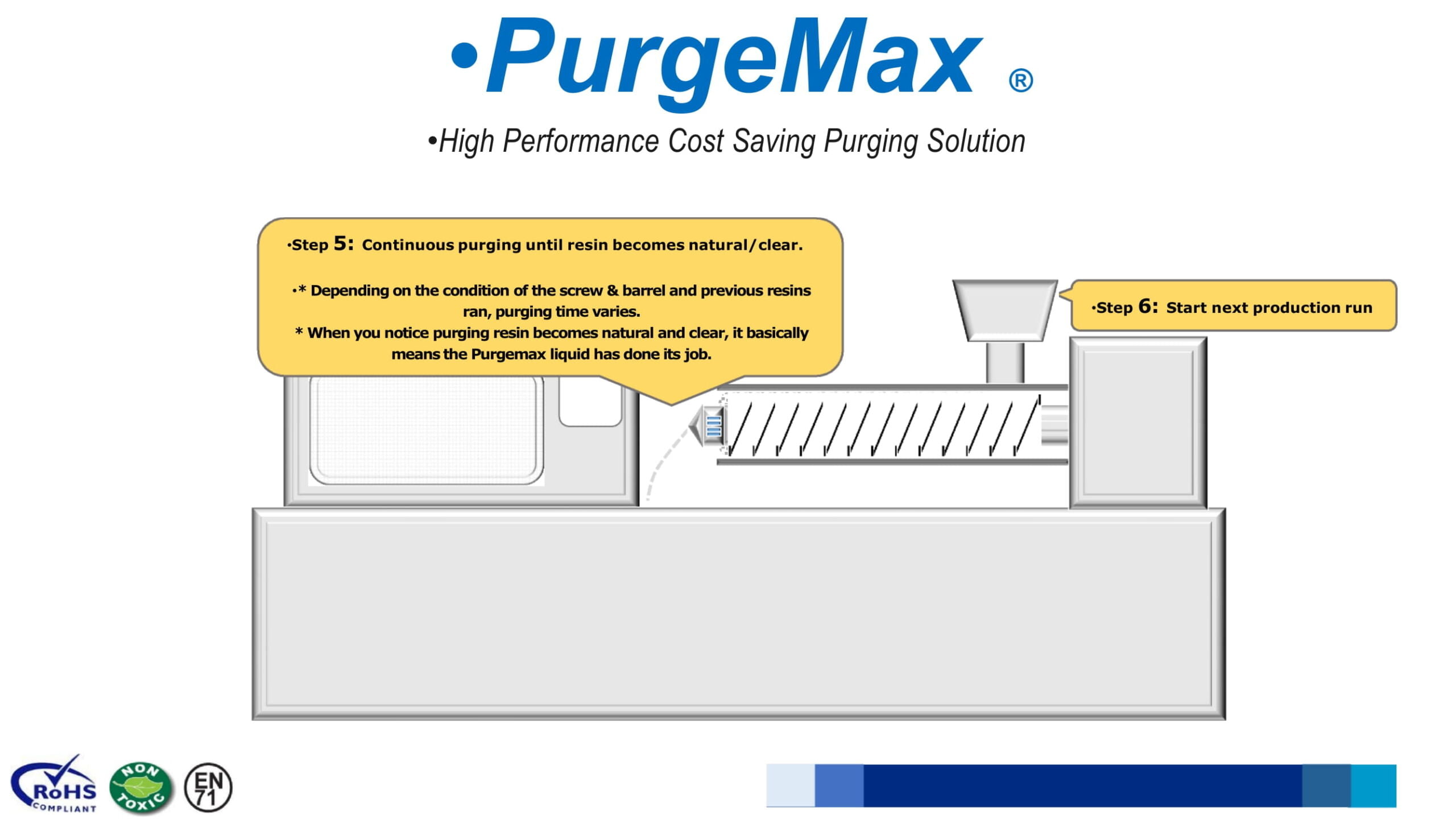

Step 5

Maintain continuous purging until resin appears natural and clean.

Step 6

The Purging process is complete, resume with standard procedures for next job.

* With applications that require more than one PurgeMax® (refer PurgeMax Usage Chart), place one PurgeMax® into the hopper and follow with a small amount of purging resin, repeat until the entire dosage has been added then charge the barrel with purging resin. The user can also place a small amount of purging resin before using PurgeMax®.

** For hot runner and manifold systems, purge a small amount from the nozzle before proceeding to open mold purging or injection.

NOTE: A small amount of smoke may appear during purging. Although not very common, it is a normal condition.

NOTE: How many kilograms of resin should be used for purging?

First time user, prepare 50% of your average purging resin quantity used.

Example : Normal purging resin quantity is 10kg. Prepare 5kg of your usual purging resin (crushing/original), follow the Purging Guideline and start purging process. Maintain continuous purging until the purging resin becomes natural and clean. The total quantity of purging resin used for purging will end up as waste; the rest will be your saving.